The wheel-type compost turning machine is suitable for the fermentation and turning of organic waste such as large-span and high-depth livestock and poultry manure, sludge garbage, sugar factory filter mud, dross cake and straw sawdust, and is widely used in organic fertilizers Fermentation and dehydration operations in plants, compound fertilizer plants, sludge waste plants, gardening farms, and Agaricus bisporus planting plants.

Features:

1. The throwing depth can reach 1.5-2 meters;

2. Large turning span: the maximum turning width can reach 30 meters;

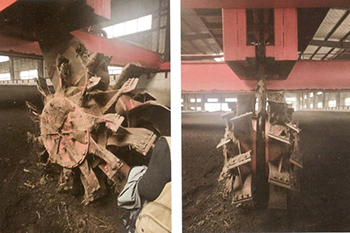

3. Low energy consumption for turning and throwing: a unique energy-saving and high-efficiency transmission mechanism is adopted, which reduces energy consumption by 70% compared with traditional turning and throwing equipment under the same workload; there is no dead angle for turning and throwing: symmetrical turning of the roulette, under the displacement of the speed-regulating shift trolley Turning without dead ends;

4. During the operation of the compost turner, the raw material aggregates are fully contacted and mixed with the air, and a lot of fresh air can be cultivated in the stockpile, which is conducive to aerobic micro-fermentation, and the pile temperature rises. When the temperature is high, the supplement of fresh air can Cool down the pile temperature. It forms the shape of high-temperature exchange, and various beneficial microorganisms grow and multiply in the temperature range to which they are adapted;

5. The compost turner system can process the materials into small clumps, making the viscous and dense raw material piles loose and elastic, forming a suitable porosity.

The size can be customized according to customer requirements.