The Organic Fertilizer Production Line has rich raw material resources. The equipment may differ for

different materials.

1.Animal waste, animal manure, such as chicken, pig, cattle, sheep, horse, rabbit, animal residue, such as

fish meal, bone meal, feather, fur, silkworm excrement, biogas residue, etc.

2.Agricultural wastes. Crop straw, vine, soybean mean, rapeseed meal, cottonseed meal, caster bean meal, tea

seed meal, yeast powder, mushroom residue, etc.

3.Industrial waste. Vinasse, vinegar residue, manioc waste, filter mud, herb residue, furfural residue,

etc.

4.Municipal sludge. River sludge, pound sludge, ditch sludge, sea mud, lake mud, sewage sludge, humic acid,

turf, lignite, danty, organic fertilizer production line, fertilizer granules fly, ash, etc.

5. Household garbage. Kitchen waste, etc.

6.Extracted or concentrated organics, seaweed extract, fish extract, etc.

Advantages of Organic Fertilizer Production Line:

1. Adopt semi-wet material crusher, having strong adaptability to the moisture content.

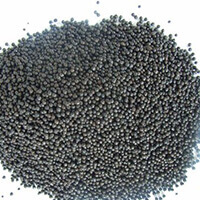

2. Granule polishing machine makes spherical granules with uniform size, smooth surface and high strength.

Suitable for connecting with various granulator.

3. Belt conveyor and other supporting equipment are used to connect the whole line.

4. Compact structure, stable performance, easy operation and maintenance.

5. The equipment is optional according to your actual requirement.