For the production process of organic fertilizer and bio-organic fertilizer, the raw materials can be selected from various livestock, poultry manure, and organic waste. The basic formula of production varies with different types and raw materials; the basic raw materials are: chicken manure, duck manure, goose, pig manure, cow manure, sheep manure, crop straw, sugar industry filter mud, bagasse, beet bagasse , wine sugar, medicine residue, furfural residue, fungus residue, bean cake, cotton kernel cake, rapeseed cake, grass carbon, etc.

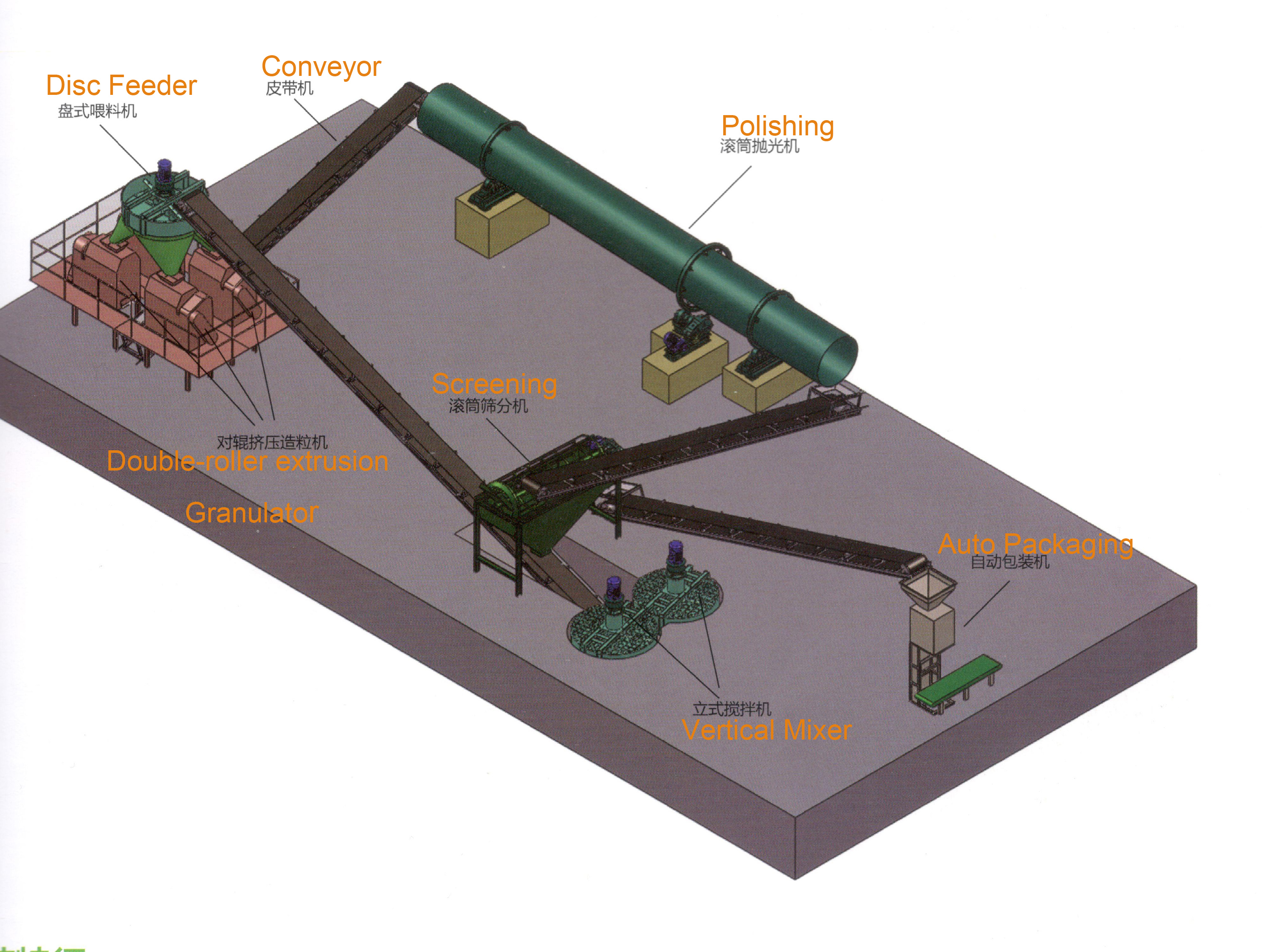

Process introduction:

1. First of all, raw materials such as animal manure should be fermented and decomposed. During the entire fermentation process, harmful bacteria can be killed and disinfected, which is also the most important in the entire organic fertilizer manufacturing process.

2. Secondly, use the organic fertilizer crushing equipment to decompose the raw materials.

3. Batching is a key step in fertilizer production. Its main function is to add appropriate ingredients in proportion to make the organic fertilizer rich in organic matter and improve its quality.

4. After the material is evenly stirred, it needs to be granulated, which is also the most important part of the whole process.

5. The material obtains high temperature through the drying process, and it needs to be cooled when it is transferred. The water produced by drying can be evaporated quickly by accelerating the air flow speed.

6. Screening is to screen out unqualified fertilizer particles, and unqualified materials will return to the production line for qualified treatment and reprocessing.

7. The finished product after sieving can be coated according to customer needs, and coating agents such as functional bacteria, release agents, brighteners, and resins can be added

8. Packaging is the last link in fertilizer equipment. In order to protect products during circulation, facilitate storage and transportation, and promote sales, packaging is carried out according to certain technical methods.

The machinery and equipment used include. According to different types of raw materials and different production requirements of customers, one or more different machines and equipment can be selected for combination to form a complete production line. Batching machine, mixer, granulator, pulverizer, drum screening machine, hot air stove, dryer, cooling machine, coating machine, automatic packaging machine, dust removal room, round throwing machine, composting and fermentation equipment.