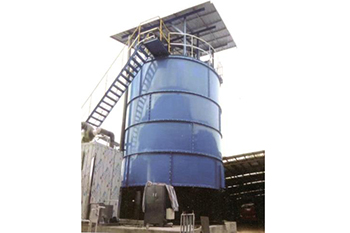

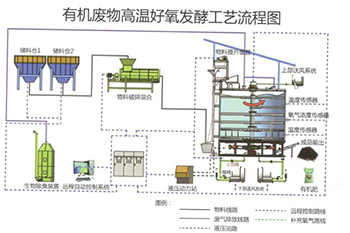

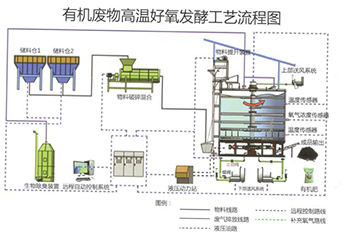

The vertical fermenter is mainly used for high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, and uses the activity of microorganisms to biodecompose the organic matter in the waste to make it harmless and stable , reduction, resource utilization integrated sludge treatment equipment. The working principle of the equipment is to mix waste (livestock and poultry manure, kitchen waste, domestic sludge, etc.), biomass (straw and sawdust, etc.) and return materials evenly in a certain proportion, so that the moisture content reaches the design requirement of 60%-65% After entering the three-dimensional aerobic system, by adjusting the moisture, oxygen content and temperature changes of the raw materials, the materials can be fully aerobically fermented and decomposed. The heat released during the decomposition process can increase the temperature of the materials themselves, and the maximum temperature can reach 80°C. The moisture in the material is evaporated as the temperature rises, and part of the organic matter is decomposed, thereby reducing the volume of the pile and reaching the waste reduction treatment. The temperature of the organic fertilizer fermentation tank is controlled between 55°C and 60°C through ventilation, oxygenation, stirring, etc., to reach the optimum temperature for material fermentation treatment. At this temperature, a large number of pathogenic bacteria and parasites in the pile can be eliminated Insects are killed, and at the same time, the deodorization system is used to carry out biological odor treatment on the discharged gas to achieve the purpose of harmless treatment. The product after high-temperature aerobic fermentation can be used for soil improvement, landscaping, landfill covering soil, etc.

Features:

1. High-temperature aerobic fermentation, using high-temperature biological bacteria technology, low energy consumption and low operating costs;

2. The equipment occupies a small area and has a high degree of automation, and the fermentation process can be completed under the control of one person;

3. Through the biological deodorization equipment to achieve gas discharge standards, no secondary pollution;

4. The heat preservation design of the main body and auxiliary heating ensure the normal operation of the equipment in low temperature environment.

| Model | Equipment Size (length*width*height) | Mix Capacity | Power | Heating system | Aeration system | Control System | Feeding and discharging system |

| YZGF-10 | 3.5m*2.4m*2.9m | > 10m3 (water capacity) | 5.5kw | Electric heating | Air compressor aeration equipment (included in the whole machine) | 1 set of automation control system (included in the whole machine) | Conveying (included in the whole machine) |

| YZGF-20 | 3.5m*2.4m*2.9m | > 20m3 (water capacity) | 11kw | ||||

| YZGF-30 | 3.5m*2.4m*2.9m | > 30m3 (water capacity) | 15kw |