Double-bucket automatic quantitative packaging scale is used in automatic quantitative packaging in industrial and agricultural automatic production. The whole weighing process is controlled by computer, and the machine works automatically. It has the advantages of fast weighing speed, high weighing accuracy, labor saving, labor saving, simple operation and convenient maintenance.

Features:

1. Use high stability and high precision load cells and weighing modules; the interface is simple to operate and intuitive to display;

2. Independent packaging weight input and weighing weight display window, the display window adopts high-brightness LED display; the menu operation is simple, intuitive and friendly; manual assistance in bagging (or bucket), pneumatic bag clamping;

3. The independent weighing system weighs, with high weighing accuracy and fast speed, and the weighing sensor adopts Toledo weighing sensor;

4. The asynchronous motor controls the screw feeding, the frequency converter controls the adjustment speed, and the large and small double screw fast and slow metering and feeding, with high control accuracy;

5. The whole machine is made of stainless steel except for the motor, cylinder, electrical accessories, pneumatic components and sewing machine.

Machine structure composition:

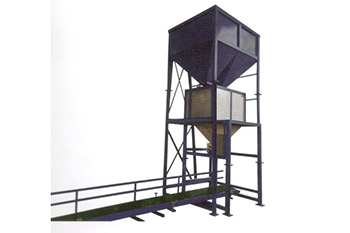

The fully automatic computer quantitative packaging scale is mainly composed of four major parts: automatic weighing device, conveying device, sewing device, and computer control. It has the characteristics of compact structure, beautiful appearance, stable operation, energy saving, convenient operation and accurate weighing.

The main engine adopts fast, medium and slow three-speed feeding and special feeding auger structure, advanced digital frequency conversion technology, sampling processing technology, anti-interference technology, and realizes automatic error compensation and correction.

It is suitable for quantitative packaging of powder and granular materials.